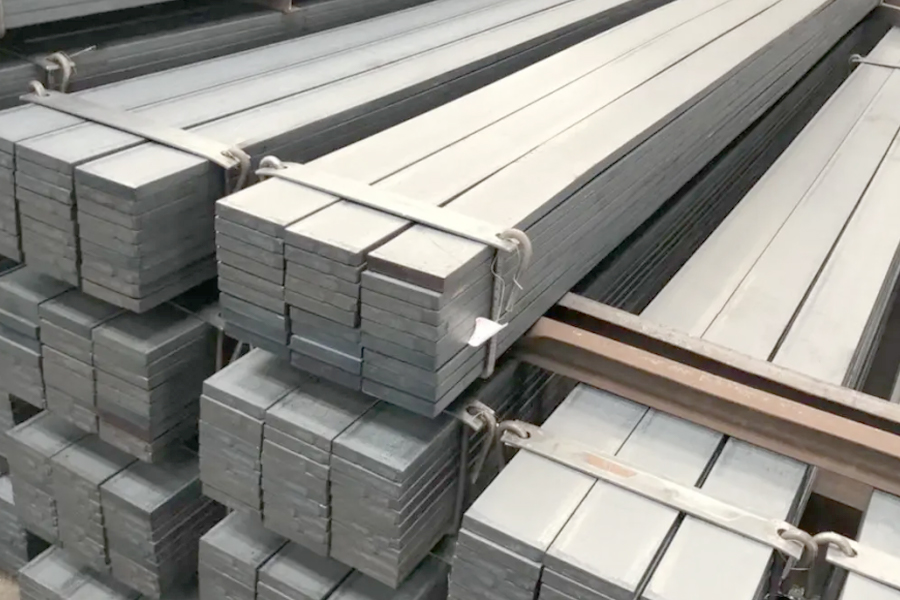

Stainless Steel Flat Steel, as an important metal material, has become one of the indispensable basic materials in modern industry with its excellent performance and wide application fields. Whether it is construction, machinery manufacturing or decoration engineering, stainless steel flat steel has won the favor of the market with its high strength, corrosion resistance and aesthetics.

The core advantage of stainless steel flat steel lies in its corrosion resistance. Due to the presence of chromium, a dense oxide film will form on the surface, which can effectively resist the erosion of acid, alkali, salt spray and other chemicals. This makes it particularly suitable for use in humid, high temperature or corrosive environments.

High Strength and Durability

Stainless steel flat steel has high tensile strength and hardness, and can withstand large loads and impact forces. This feature makes it an ideal choice for structural support, machinery and equipment manufacturing and other fields.

Aesthetics and easy processing

Stainless steel flat steel has a high surface finish, and after polishing, it can present a mirror effect, which is very decorative. At the same time, it is easy to cut, weld and bend, and can be easily processed into various shapes to meet different design requirements.

Environmental protection and sustainability

Stainless steel is a fully recyclable material with a long service life and no harmful substances released, which is in line with the development trend of green environmental protection.

Diverse specifications

Stainless steel flat bar can be customized according to thickness, width and length to adapt to different application scenarios, and suitable specifications can be found from precision instruments to large building structures.

Production process of stainless steel flat bar

The production process of stainless steel flat bar mainly includes the following key steps:

Raw material preparation

The raw material of stainless steel flat bar is usually stainless steel billet, which is made by smelting raw materials such as iron ore, chromium, nickel, etc. Select the appropriate stainless steel grade according to the end use.

Hot rolling or cold rolling

The billet enters the rolling mill after heating and is initially formed into flat steel through hot rolling process. If higher precision and surface quality are required, it is further processed by cold rolling process.

Annealing and pickling

The hot-rolled stainless steel flat bar needs to be annealed to eliminate internal stress and improve its mechanical properties. The surface oxide layer is then removed by pickling to ensure the smoothness and corrosion resistance of the product.

Cutting and finishing

According to customer requirements, stainless steel flat bars are cut into specified lengths and polished, brushed or otherwise surface treated to enhance appearance and functionality.

Application areas of stainless steel flat bars

Construction engineering

In the construction industry, stainless steel flat bars are often used as structural supports, stair handrails, guardrails, and decorative lines. Its corrosion resistance and aesthetics make it an ideal choice for interior and exterior decoration.

Mechanical manufacturing

Stainless steel flat bars are widely used in the manufacture of mechanical equipment, such as drive shafts, frame structures, and components. Its high strength and wear resistance can meet the use requirements under complex working conditions.

Transportation

In the automotive, shipbuilding and rail transportation fields, stainless steel flat bars are used to manufacture body frames, chassis components, and ship decks. Its lightweight and corrosion resistance help improve the safety and life of vehicles.

Chemical and petroleum industries

Chemical equipment, storage tanks, and piping systems often use stainless steel flat bars because they can resist the erosion of strong acids, strong alkalis, and other corrosive media, ensuring long-term and stable operation of the equipment.

Home and Decoration

Stainless steel flat bar is widely used in kitchen utensils, furniture accessories and interior decorations due to its unique metallic texture and easy processing. For example, stainless steel countertops, door frames and display racks are common in modern home designs.

Future development trend of stainless steel flat bar

With the advancement of science and technology and changes in market demand, stainless steel flat bar is developing in the following directions:

High-performance material research and development

In the future, the research and development of new stainless steel alloys will further enhance the high temperature resistance, corrosion resistance and fatigue resistance of flat bar to meet the needs of high-end fields such as aerospace and nuclear energy.

Intelligent production

With the help of artificial intelligence and automation technology, the production of stainless steel flat bar will be more efficient and precise, thereby reducing production costs and improving product quality.

Green manufacturing

With the global attention to sustainable development, the production process of stainless steel flat bar will pay more attention to energy conservation and emission reduction, and promote the recycling of scrap steel to maximize the utilization of resources.

Customized service

With the increasing demand of consumers for personalized products, the production of stainless steel flat bar will be more flexible in the future, and customized specifications and surface treatment solutions can be provided according to customer requirements.

Stainless steel flat bar has become an important part of modern industry with its excellent performance and wide range of applications. Whether in the fields of construction, transportation or chemical industry, it has demonstrated irreplaceable value. In the future, with the continuous innovation of technology and the growth of market demand, stainless steel flat steel will surely play a greater role in more fields and contribute to the sustainable development of human society.

English

English русский

русский عربى

عربى 中文简体

中文简体