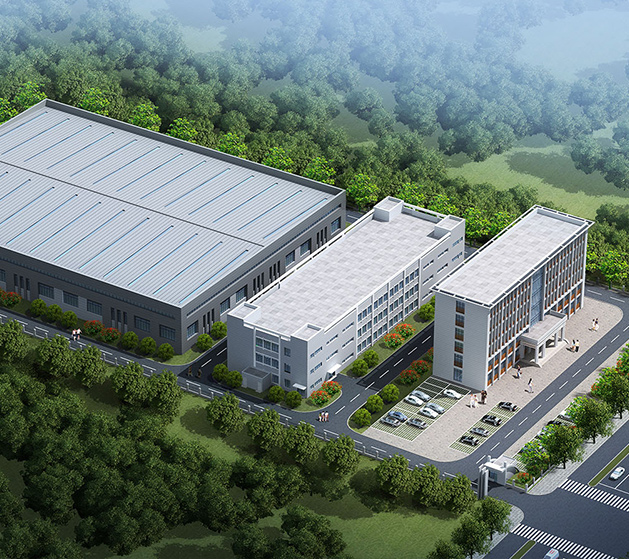

Wuxi Chengfeng Metal Technology Co., Ltd.

A company integrating design, R&D, manufacturing, sales and service.

Q. How long will it take to get a reply after we send you an inquiry?

On working days, we will reply to you within 12 hours of receiving the inquiry.Q. Are you a direct manufacturer or a trading company?

We are a factory. As Hastelloy Alloy Manufacturers, we produce and sell by ourselves.Q. What products can you provide?

We focus on the trade and sales of stainless steel and nickel-based alloy steel raw materialsQ. How about your company's production capacity?

Our material warehouse has a huge inventory of 20,000 tons of coils, providing us with strong supply chain security. Supply Hastelloy Alloy wholesale.

Quick Contact

Recent News

-

Intustry News 2025-01-17

Stainless steel pipes have earned a distinguished reputation in the food industry, owing to their re...

View More -

Intustry News 2025-01-10

In the world of construction and structural engineering, the materials used must provide the right b...

View More -

Intustry News 2025-01-03

With the growing global demand for high-performance and durable materials, Stainless Steel Flat Stee...

View More -

Intustry News 2024-12-23

Stainless steel flat steel often referred to as flat bar, is a widely used material in construction,...

View More

Hastelloy Alloy Industry knowledge

The characteristics and uses of Wuxi Chengfeng Metal Technology Co., Ltd.'s Hastelloy Alloy

Wuxi Chengfeng Metal Technology Co., Ltd. offers a wide range of Hastelloy alloys that are renowned for their exceptional corrosion resistance and mechanical properties. These alloys are widely used across various industries due to their ability to withstand harsh environments. Here are the characteristics and uses of Hastelloy alloys provided by Wuxi Chengfeng:

The Hastelloy alloys provided by Wuxi Chengfeng exhibit outstanding resistance to a wide variety of corrosive environments, including both oxidizing and reducing atmospheres. They can resist attacks from numerous corrosive media, such as acids, chlorides, and alkaline solutions.

Hastelloy alloys are known for their ability to resist localized corrosion, such as pitting and crevice corrosion, which can often occur in aggressive environments.

These alloys provide high resistance to stress corrosion cracking, making them suitable for applications under high stress and temperature conditions.

Hastelloy alloys have excellent thermal stability and maintain their strength and corrosion resistance even at elevated temperatures. They are suitable for applications requiring good mechanical properties at temperatures up to 1040 degrees Celsius.

The B series alloys are especially effective in reducing environments, such as hydrochloric acid, while the C series alloys are suitable for oxidizing environments. The G series alloys offer a balance of properties, making them ideal for specific industrial applications requiring thermal stability and broad-spectrum corrosion resistance.

This alloy contains nickel and molybdenum and is known for its excellent resistance to reducing environments, such as hydrochloric acid. It resists the formation of grain boundary carbide precipitation during welding, which allows for preservation of corrosion resistance in the welded condition.

An enhanced version of B-2, B-3 offers improved thermal stability and resistance to hydrochloric acid at any concentration and temperature. It also resists localized corrosion, making it suitable for more aggressive chemical processes.

A nickel-chromium-molybdenum alloy, C-4 offers good thermal stability and resistance to stress corrosion cracking and oxidation. It performs well in temperature ranges from 650°C to 1040°C, making it suitable for high-temperature industrial processes.

Known for its enhanced corrosion resistance, C-22 can withstand a broader range of oxidizing media than C-4 and C-276, making it ideal for acid processing, waste treatment, and offshore applications. It also provides excellent resistance to pitting, crevice corrosion, and intergranular attack.

One of the most versatile alloys, C-276 offers superior corrosion resistance in both reducing and oxidizing environments. It is highly resistant to chloride-induced corrosion, making it suitable for chemical processing and marine applications.

This alloy provides excellent resistance to phosphoric acid and other strongly oxidizing acids, making it ideal for applications in the fertilizer industry and chemical processing.

Offers improved resistance to pitting and crevice corrosion in wet process phosphoric acid production. It also provides thermal stability in a wide range of chemical processing conditions.

Hastelloy alloys from Wuxi Chengfeng are used in various industries due to their superior corrosion resistance and mechanical strength. Here are some common applications:

Hastelloy alloys are widely used in the production and processing of chemicals, where corrosive environments are common. They are suitable for reactors, heat exchangers, piping, valves, and vessels that handle acids, solvents, and alkalis.

In the petrochemical industry, Hastelloy alloys are used for catalyst reactors, high-temperature equipment, and components exposed to sour gas environments.

FGD systems require materials that can resist the corrosive effects of sulfur oxides, chlorides, and other contaminants. Hastelloy alloys, particularly C-276 and C-22, are ideal for use in absorbers, ducts, dampers, scrubbers, and other components within FGD systems.

The pulp and paper industry often involves exposure to corrosive chemicals such as bleaches, acids, and alkalis. Hastelloy alloys are used in digesters, bleach washers, and other processing equipment to ensure longevity aotection and Waste Treatment

In waste treatment facilities, where aggressive chemical environments are common, Hastelloy alloys are used in incinerators, piping, pumps, and heat exchangers. Their resistance to corrosive leachates and chemicals makes them suitable for hazardous waste processing.

In the pharmaceutical industry, Hastelloy alloys are used in the manufacturing of equipment for drug production where high purity and resistance to corrosion are essential. They are used in reactors, heat exchangers, and mixing tanks.

Hastelloy alloys are employed in the aerospace industry for engine components, exhaust systems, and heat shields that experience high temperatures and corrosive conditions.

In marine environments, Hastelloy alloys, especially C-series alloys, are used for marine hardware, submarine components, and offshore oil and gas equipment due to their resistance to seawater corrosion.

Wuxi Chengfeng ensures that all Hastelloy alloys meet strict quality control standards, providing consistent material performance.

The company offers various grades of Hastelloy alloys, ensuring that there is a suitable material for each specific application, from high-temperature processes to highly corrosive chemical environments.

Wuxi Chengfeng's ability to customize alloys to meet the unique needs of different industries provides customers with tailored solutions. The company’s expertise in metallurgy ensures that clients receive optimal material recommendations.

Wuxi Chengfeng Metal Technology Co., Ltd. offers a comprehensive selection of Hastelloy alloys, suitable for various industrial applications requiring corrosion resistance and mechanical stability. Their B, C, and G series alloys provide tailored solutions for chemical processing, environmental protection, petrochemical, pulp and paper, aerospace, and marine industries. With high-quality manufacturing practices, diverse alloy options, and customization capabilities, Wuxi Chengfeng ensures that their Hastelloy alloys meet the demanding requirements of modern industrial applications.

English

English русский

русский عربى

عربى