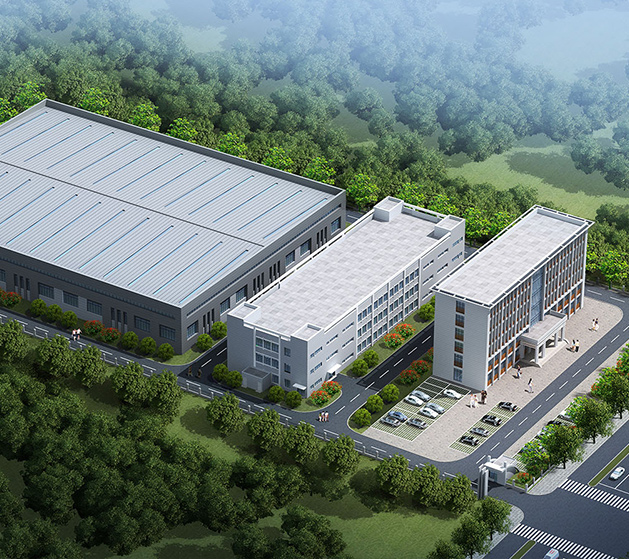

Wuxi Chengfeng Metal Technology Co., Ltd.

A company integrating design, R&D, manufacturing, sales and service.

Q. How long will it take to get a reply after we send you an inquiry?

On working days, we will reply to you within 12 hours of receiving the inquiry.Q. Are you a direct manufacturer or a trading company?

We are a factory. As Stainless Steel Plates Manufacturers, we produce and sell by ourselves.Q. What products can you provide?

We focus on the trade and sales of stainless steel and nickel-based alloy steel raw materialsQ. How about your company's production capacity?

Our material warehouse has a huge inventory of 20,000 tons of coils, providing us with strong supply chain security. Supply Stainless Steel Plates wholesale.

Quick Contact

Recent News

-

Intustry News 2025-01-17

Stainless steel pipes have earned a distinguished reputation in the food industry, owing to their re...

View More -

Intustry News 2025-01-10

In the world of construction and structural engineering, the materials used must provide the right b...

View More -

Intustry News 2025-01-03

With the growing global demand for high-performance and durable materials, Stainless Steel Flat Stee...

View More -

Intustry News 2024-12-23

Stainless steel flat steel often referred to as flat bar, is a widely used material in construction,...

View More

Stainless Steel Plates Industry knowledge

Characteristics and uses of Wuxi Chengfeng Metal's Stainless Steel Plates

Wuxi Chengfeng Metal Technology Co., Ltd. is a comprehensive industry and trade enterprise that excels in providing stainless steel and nickel-based alloy raw materials, as well as customized production and processing services. As a leader in the metal industry, the company offers a diverse range of stainless steel plates, each tailored to specific industrial needs and characterized by unique properties. With a team of experienced technical experts, skilled welders, and a robust quality inspection team, Wuxi Chengfeng ensures that its products consistently meet the highest standards before reaching customers.

The types of stainless steel plates available on the market are varied, with five primary categories being widely recognized: austenitic stainless steel, martensitic stainless steel, ferritic stainless steel, duplex stainless steel, and precipitation-hardening stainless steel. Among these, austenitic stainless steel is the most commonly used. Each type offers distinct characteristics that suit different applications, depending on the mechanical properties and corrosion resistance requirements.

Austenitic stainless steel is the most widely used and versatile type of stainless steel, representing a significant portion of Wuxi Chengfeng’s product offerings. Characterized by its high chromium and nickel content, this type exhibits excellent corrosion resistance, toughness, and formability. One of the standout features of austenitic stainless steel is its non-magnetic nature and the ability to maintain its mechanical properties across a wide temperature range, from cryogenic temperatures up to high heat.

Applications of austenitic stainless steel plates are diverse, including their use in kitchen equipment, chemical processing, food processing, construction, and medical devices. The excellent resistance to acids, alkalis, and chlorides makes these plates ideal for use in corrosive environments, such as marine applications and chemical plants. Additionally, austenitic stainless steel is commonly used in decorative architectural applications, thanks to its ability to be polished to a mirror-like finish.

Martensitic stainless steel differs from austenitic types due to its lower chromium content and the presence of carbon, which allows it to be hardened through heat treatment. It is magnetic and typically less corrosion-resistant than austenitic stainless steel but offers high strength and hardness.

These properties make martensitic stainless steel ideal for applications requiring cutting edges or high wear resistance, such as in surgical instruments, knives, shafts, and turbine blades. Wuxi Chengfeng ensures precise quality control during the heat treatment process to optimize the hardness and mechanical properties of martensitic stainless steel plates.

Ferritic stainless steels are primarily composed of chromium and contain little or no nickel, making them a more cost-effective alternative to austenitic types. They exhibit good resistance to corrosion and oxidation, particularly in environments free from chloride exposure. Ferritic stainless steel is magnetic and known for its better thermal conductivity and lower thermal expansion compared to austenitic stainless steel.

Common uses include automotive exhaust systems, heat exchangers, and indoor architectural elements. Their good corrosion resistance, combined with an affordable cost, makes ferritic stainless steel plates suitable for situations where moderate corrosion resistance is acceptable.

Duplex stainless steels are a combination of austenitic and ferritic structures, providing a balance of strength and corrosion resistance. They offer higher strength than either austenitic or ferritic stainless steel, as well as improved resistance to stress corrosion cracking and pitting.

These plates are particularly beneficial in chemical processing, oil and gas exploration, and marine applications where exposure to harsh environments is common. Wuxi Chengfeng's production capabilities allow the customization of duplex stainless steel plates for specific industrial requirements, ensuring optimal performance in challenging conditions.

Precipitation-hardening stainless steels combine the properties of austenitic and martensitic stainless steel, providing high strength and hardness with good corrosion resistance. The hardening process involves adding elements like aluminum, copper, or titanium, which allow the steel to be strengthened through heat treatment.

They are used in aerospace components, nuclear reactors, and high-stress mechanical parts, where their ability to maintain strength under high-stress conditions is crucial. The team at Wuxi Chengfeng leverages advanced heat treatment techniques to produce precipitation-hardening stainless steel plates that meet the rigorous demands of these industries.

At Wuxi Chengfeng Metal Technology Co., Ltd., every stainless steel plate undergoes a stringent quality inspection process. The company's senior technical experts carefully interpret design drawings to ensure that production aligns perfectly with the intended specifications. Skilled welders and riveters complete assembly work with precision, while the company’s huge inventory of 20,000 tons of coils provides a stable supply chain that can cater to the needs of large enterprises.

In addition to standard offerings, customization services enable clients to request specific grades, dimensions, and surface finishes. Whether it is a need for special coatings, tailored dimensions, or heat-treated plates, Wuxi Chengfeng can accommodate diverse requirements to deliver products that meet the highest industry standards.

Wuxi Chengfeng Metal Technology Co., Ltd. is dedicated to providing stainless steel solutions that cater to a broad range of industrial needs. With a comprehensive selection of stainless steel plates, the company supports various industries by offering high-quality materials that feature outstanding mechanical properties and corrosion resistance. By maintaining a strong focus on quality, customization, and customer satisfaction, Wuxi Chengfeng stands out as a trusted partner in the global metal industry.

English

English русский

русский عربى

عربى