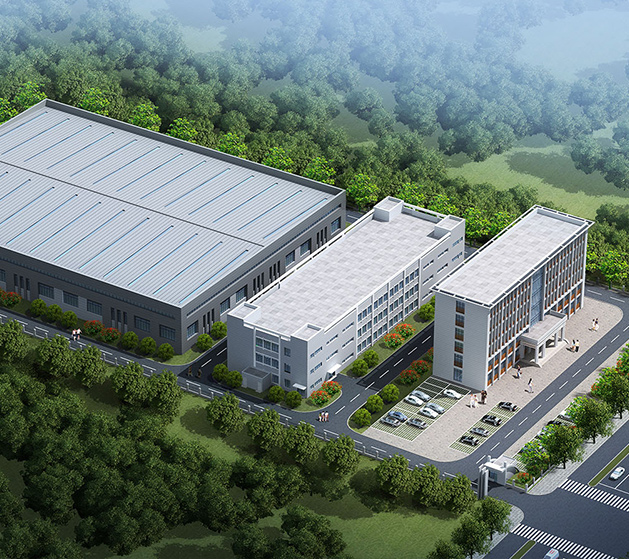

Wuxi Chengfeng Metal Technology Co., Ltd.

A company integrating design, R&D, manufacturing, sales and service.

Q. How long will it take to get a reply after we send you an inquiry?

On working days, we will reply to you within 12 hours of receiving the inquiry.Q. Are you a direct manufacturer or a trading company?

We are a factory. As Titanium Alloy Manufacturers, we produce and sell by ourselves.Q. What products can you provide?

We focus on the trade and sales of stainless steel and nickel-based alloy steel raw materialsQ. How about your company's production capacity?

Our material warehouse has a huge inventory of 20,000 tons of coils, providing us with strong supply chain security. Supply Titanium Alloy wholesale.

Quick Contact

Recent News

-

Intustry News 2025-01-17

Stainless steel pipes have earned a distinguished reputation in the food industry, owing to their re...

View More -

Intustry News 2025-01-10

In the world of construction and structural engineering, the materials used must provide the right b...

View More -

Intustry News 2025-01-03

With the growing global demand for high-performance and durable materials, Stainless Steel Flat Stee...

View More -

Intustry News 2024-12-23

Stainless steel flat steel often referred to as flat bar, is a widely used material in construction,...

View More

Titanium Alloy Industry knowledge

The characteristics and uses of Wuxi Chengfeng Metal Technology Co., Ltd.'s Titanium Alloy

Wuxi Chengfeng Metal Technology Co., Ltd. offers a wide range of titanium alloys known for their lightweight, high strength, excellent corrosion resistance, and ability to perform well in extreme conditions. These properties make titanium alloys from Wuxi Chengfeng suitable for use in aerospace, medical, automotive, marine, and chemical industries. Below are the characteristics and uses of Wuxi Chengfeng's titanium alloy products:

Titanium alloys provided by Wuxi Chengfeng are recognized for their outstanding strength while being significantly lighter than steel, which is essential for applications requiring lightweight materials without compromising strength.

These alloys exhibit excellent resistance to corrosion, especially against chloride-containing environments, seawater, and various chemical solutions, making them suitable for marine and chemical applications.

Titanium alloys have good performance at elevated temperatures, which allows them to be used in high-temperature environments, such as aircraft engines and rocket components.

The titanium alloys are biocompatible, making them ideal for use in medical implants and surgical devices.

Wuxi Chengfeng offers various types of titanium alloys, each with different chemical compositions and mechanical properties to cater to specific industrial requirements.

It has a low alloy content and high corrosion resistance, making it suitable for applications with low to moderate strength requirements.

It is commonly used in heat exchangers, desalination equipment, chemical storage tanks, and other corrosion-resistant equipment.

These alloys feature high strength and good heat resistance, making them suitable for high-temperature applications. They have limited plasticity but excellent creep resistance, maintaining their mechanical properties at elevated temperatures.

Primarily used in the aerospace industry, these alloys are ideal for manufacturing aircraft engine compressor components, rocket structures, and missile casings.

These alloys exhibit good plasticity, toughness, and processability at room temperature, allowing them to be formed into complex shapes. They combine moderate strength with better ductility than α alloys, making them versatile.

Commonly used in the manufacturing of aircraft structural components, automotive parts, sports equipment, and medical implants.

Known for their high strength, good weldability, and excellent corrosion resistance, β titanium alloys also retain their strength at high temperatures, making them suitable for extreme conditions.

Used in marine engineering, chemical equipment, high-performance automotive components, and aerospace applications. Their corrosion resistance is particularly advantageous in offshore and subsea equipment.

Titanium alloys are widely used in the manufacture of aircraft components, such as engine parts, landing gear, and airframe structures, due to their high strength-to-weight ratio and resistance to high temperatures.

They are also used in rocket and missile structures where lightweight and heat-resistant materials are critical for performance.

The biocompatibility of titanium alloys makes them suitable for medical implants, including bone plates, dental implants, and hip joints. They are also used in surgical instruments due to their corrosion resistance and non-reactive properties.

In the sports industry, titanium alloys are utilized for high-end sports equipment, such as golf clubs, bicycle frames, and racket frames, providing durability and lightweight properties.

Titanium alloys are used in the automotive sector to improve the performance of engine components, such as connecting rods, exhaust systems, and valves. Their high strength and low weight help to reduce fuel consumption and enhance engine efficiency.

They are also applied in racing cars, where lightweight materials are essential for speed and performance.

In marine environments, titanium alloys are employed in the construction of subsea structures, offshore drilling equipment, and ship components, where resistance to seawater corrosion is crucial.

Their use extends to desalination plants and other marine engineering applications, where durability in corrosive conditions is essential.The chemical resistance of titanium alloys makes them suitable for use in chemical processing equipment, such as reactors, heat exchangers, and storage tanks.

They are also used in corrosive fluid handling applications, such as piping systems and valves that transport aggressive chemicals.

Wuxi Chengfeng provides tailored solutions for different industrial needs, offering specific alloy grades and customized titanium products to meet unique application requirements.

The company ensures that all titanium alloys meet rigorous quality control standards, guaranteeing consistent performance.

With a variety of alloy types and grades, Wuxi Chengfeng offers solutions for high-temperature, high-corrosion, and lightweight applications.

Wuxi Chengfeng Metal Technology Co., Ltd. supplies a diverse selection of titanium alloys, catering to the needs of industries such as aerospace, medical, automotive, marine, and chemical engineering. Their range includes industrial pure titanium, α, near-α, α+β, and β titanium alloys, each with unique characteristics suited to specific applications. Whether for high-temperature environments, corrosive conditions, or biocompatible medical devices, Wuxi Chengfeng's titanium alloys provide superior quality and performance.

English

English русский

русский عربى

عربى