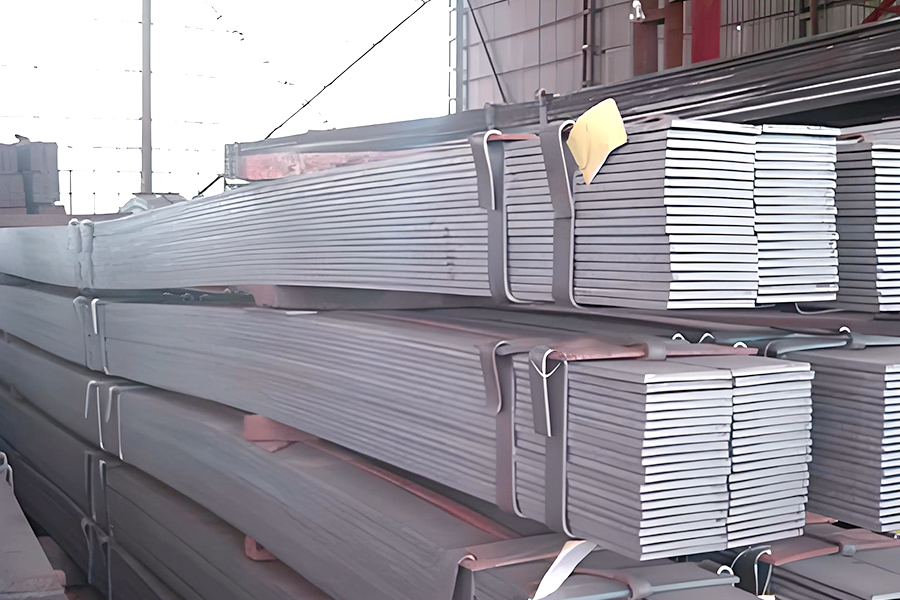

Stainless steel flat steel is rapidly gaining prominence in modern manufacturing due to its combination of strength, durability, and corrosion resistance. Used across a wide range of industries, from construction and automotive to electronics and medical devices, stainless steel flat steel is proving to be an essential material for creating high-quality products that withstand the test of time. As industries continue to evolve and embrace sustainable practices, the demand for stainless steel flat steel is expected to grow, driving innovations that help meet modern challenges.

One of the defining features of stainless steel flat steel is its non-corrosive nature, which makes it highly resistant to rust and tarnish, even when exposed to harsh environments or chemicals. This quality is especially important in industries where hygiene and long-term durability are crucial, such as the food and beverage, medical, and construction sectors.

The high chromium content in stainless steel flat steel gives it excellent resistance to rust, corrosion, and staining. This makes it ideal for applications in environments exposed to moisture, chemicals, or extreme weather conditions. The durability of stainless steel ensures that products made from it have a longer lifespan, reducing the need for frequent replacements and maintenance.

Stainless steel flat steel is known for its superior strength and structural integrity. It is strong enough to support heavy loads and withstand impact, making it an ideal material for structural components in buildings, bridges, and machinery. Additionally, its resistance to wear and tear ensures that it remains functional and reliable in demanding applications.

Stainless steel flat steel has a smooth, polished surface that provides an attractive, modern appearance. This is particularly valuable in industries such as architecture and interior design, where both functionality and aesthetics are important. Stainless steel’s reflective surface is also resistant to staining, helping to maintain a clean, pristine look over time.

Stainless steel flat steel can withstand high temperatures, making it suitable for applications in environments where heat resistance is required. From industrial equipment to kitchen appliances, stainless steel maintains its strength and performance even under extreme thermal conditions.

The non-porous surface of stainless steel makes it easy to clean and maintain. Unlike other metals, stainless steel does not require frequent polishing or protective coatings, which helps reduce the cost and effort of upkeep. This is especially advantageous in industries such as food processing, healthcare, and pharmaceuticals, where hygiene and cleanliness are critical.

Stainless steel is 100% recyclable, making it an eco-friendly material choice. As industries place increasing importance on sustainability, stainless steel flat steel’s recyclability makes it an attractive option for manufacturers seeking to reduce their environmental impact. Using recycled stainless steel reduces energy consumption and raw material extraction, contributing to a circular economy.

The versatility of stainless steel flat steel allows it to be used in a wide range of industries and applications. Below are some key areas where this material excels:

In the construction sector, stainless steel flat steel is used for structural components, reinforcement bars, cladding, and façades. Its corrosion resistance and strength make it ideal for buildings, bridges, and other infrastructure projects that are exposed to the elements. Stainless steel’s long-term durability and low maintenance make it an economical choice for both residential and commercial construction.

Stainless steel flat steel is widely used in the automotive sector for components such as exhaust systems, body panels, and chassis. Its resistance to corrosion from road salt and exposure to the elements is critical in ensuring the longevity of vehicles. Furthermore, the lightweight nature of stainless steel contributes to fuel efficiency and overall performance.

In industries that demand the highest standards of hygiene, such as food processing and healthcare, stainless steel flat steel is a go-to material. Its resistance to bacterial growth and ease of cleaning make it ideal for equipment such as processing machinery, countertops, sinks, and medical devices. Stainless steel’s non-reactivity with food or medical substances ensures the integrity and safety of the products being handled.

In the consumer electronics and home appliance industries, stainless steel flat steel is used for manufacturing components like casings, panels, and heat exchangers. Its strength, sleek appearance, and heat resistance make it an ideal material for high-end electronics such as refrigerators, ovens, and laptops.

The energy sector relies on stainless steel flat steel for power plants, pipelines, and industrial boilers. Its ability to withstand extreme temperatures and corrosion from chemicals or saltwater makes it an essential material in both renewable and traditional power generation applications, including wind turbines and oil refineries.

Stainless steel flat steel is also used in the aerospace and defense sectors, where high strength and heat resistance are essential. Aircraft components, satellite parts, and military equipment all benefit from the durability and reliability of stainless steel.

Despite its many advantages, the production and use of stainless steel flat steel face certain challenges. One major concern is the high energy consumption and environmental impact associated with the steel manufacturing process. However, ongoing advancements in technology are making the production process more energy-efficient and sustainable, with a growing emphasis on using recycled materials.

The demand for stainless steel flat steel is expected to increase in the coming years as industries continue to prioritize durability, performance, and sustainability. With growing emphasis on green building practices, renewable energy, and waste reduction, the material’s role in meeting these objectives is set to expand.

English

English русский

русский عربى

عربى 中文简体

中文简体