Stainless Steel Plate is a widely used material in modern industry and construction. With its excellent corrosion resistance, oxidation resistance and mechanical strength, stainless steel plates are used in various industries, including automobiles, construction, medical equipment, kitchen appliances and many other engineering and manufacturing fields.

Stainless steel plates are made of steel and other alloying elements (such as chromium, nickel, molybdenum, etc.) through a smelting process. They have high corrosion resistance, high temperature resistance and excellent mechanical properties. These characteristics enable them to maintain good performance in many extreme environments and extend the service life of the product. Here are a few notable features:

One of the most important features of stainless steel plates is their excellent corrosion resistance. The high content of chromium can form a thin and strong oxide film to prevent oxidation reactions from occurring. This allows stainless steel plates to remain stable for a long time in humid or corrosive environments.

Stainless steel plates can withstand high temperatures and still maintain strong mechanical strength and stability at high temperatures. They are particularly suitable for engineering projects in high temperature environments, such as boilers, heat exchangers, etc.

Stainless steel plates have high tensile and compressive strengths and can withstand large mechanical loads, so they are widely used in building structures and heavy machinery.

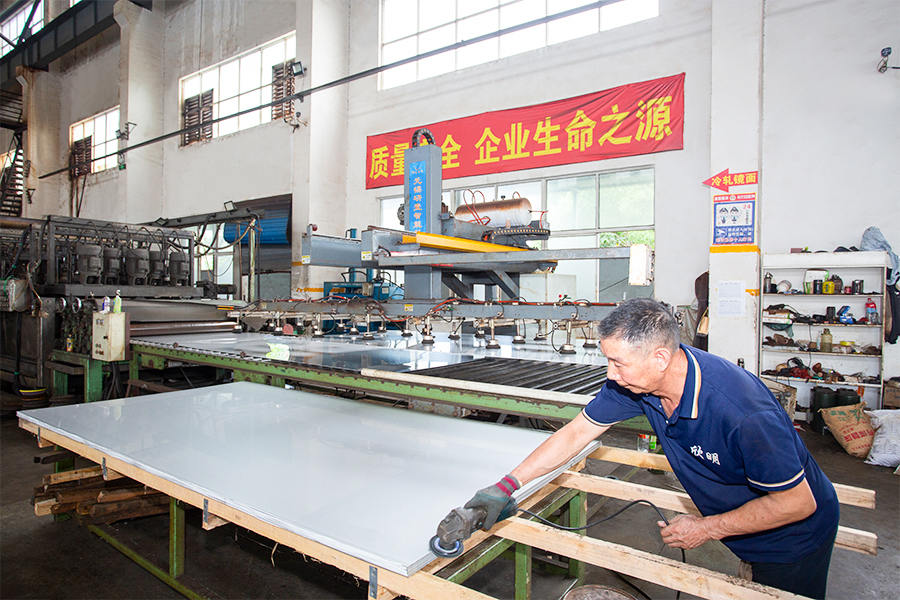

Although stainless steel plates have high hardness, they can still be processed through cutting, stamping, welding and other processes to meet various design requirements.

Stainless steel plates can be divided into many types according to their alloy composition, surface treatment and use. Common types of stainless steel plates include:

This type of stainless steel plate contains high chromium and nickel, and has excellent corrosion resistance and good ductility. It is often used in chemical equipment, food processing machinery and other fields.

This type of stainless steel plate is mainly ferrite structure, contains less nickel, and has relatively low cost, but its corrosion resistance is slightly worse than austenite. It is widely used in the automotive industry and architectural decoration.

Martensitic stainless steel plate mainly contains high carbon, which gives it good hardness and strength, and is suitable for manufacturing parts with high strength requirements such as knives and gears.

Duplex stainless steel plate is a combination of austenite and ferrite structures, with strong corrosion resistance, oxidation resistance and higher strength, and is often used in marine engineering, oil and gas industries.

Due to its excellent performance, stainless steel plates are widely used in many industries:

Stainless steel plates are often used in building facades, roofs, window frames, doors and other parts due to their weather resistance and aesthetics, especially in highly corrosive environments such as seaside and chemical processing.

Stainless steel plates also have important applications in automobile manufacturing, especially in the external structure of the car body, exhaust pipes, engine parts, etc., with good corrosion resistance and high temperature resistance.

In the food processing industry and medical equipment manufacturing, the hygiene and corrosion resistance of stainless steel plates make them an indispensable material. It is used to manufacture food processing equipment, pharmaceutical production equipment, surgical instruments, etc.

The seawater corrosion resistance of stainless steel plates makes them an important material in shipbuilding and offshore platform construction, especially in equipment and structures in marine environments, which can effectively extend the service life.

In energy industries such as oil, natural gas and nuclear energy, stainless steel plates are widely used in the manufacture of facilities such as pipelines, containers, reactors, etc. due to their strength and high temperature resistance.

With the advancement of technology and changes in market demand, the production process and application areas of stainless steel plates are also constantly developing. Here are some future development trends:

The future stainless steel plate will develop in the direction of lighter and higher strength to meet the demand for lightweight materials in modern automobiles, aerospace and other fields.

With the improvement of environmental protection requirements, more stainless steel plate production processes will adopt environmentally friendly materials and clean energy to reduce the burden on the environment.

The production process of stainless steel plates will develop in the direction of intelligence, and improve production efficiency and product quality through big data, Internet of Things and artificial intelligence technologies.

Stainless steel plates will continue to expand their application areas, especially in high-end equipment, advanced manufacturing and environmental protection projects, which will further promote the development of the industry.

As an important engineering material, stainless steel plates are widely used in construction, automobiles, food processing, medical equipment, energy and other fields with their excellent corrosion resistance, strength, high temperature resistance and good processing performance. With the development of technology, the performance and application range of stainless steel plates will continue to expand, becoming an indispensable key material in more industries.

English

English русский

русский عربى

عربى 中文简体

中文简体